Food handling plants use several warm therapy methods that run over and are listed below ambient temperature levels. These running temperature levels are vital for vital procedures in the food production procedure. Inadequate thermal effectiveness throughout toasting straight leads to expensive power losses.

Where Insulation Fits Essential Food Handling

Food handling strategies differ extensively, yet some typical instances that count on reliable warm monitoring consist of cooking, emulsifying, fermenting, sterilizing, and roasting. The assimilation of thermal insulation is a reasonably fundamental issue.

Shielded Drapes

A reliable thermal insulation option in food handling plants is the usage of lightweight thermal insulation drapes to divide particular workstations. They are likewise used in storage space applications to keep packaged foods' excellent ambient temperature levels.

A reliable thermal insulation option in food handling plants is the usage of lightweight thermal insulation drapes to divide particular workstations. They are likewise used in storage space applications to keep packaged foods' excellent ambient temperature levels.

Because insulation drapes are not a component of the food handling procedure. The silica gel-coated glass fiber textile can satisfy the requirements of thermal insulation drapes in terms of warm transmission, and silica gel-coated glass fiber textile can well meet the needs of thermal insulation drapes in terms of friendly message and also high wear resistance.

Thermal Insulation: Advantages Past Temperature level

This is one instance of how insulation can be released in a food handling plant. Yet, there is no restriction on how high-performance insulation can be used in a handling atmosphere.

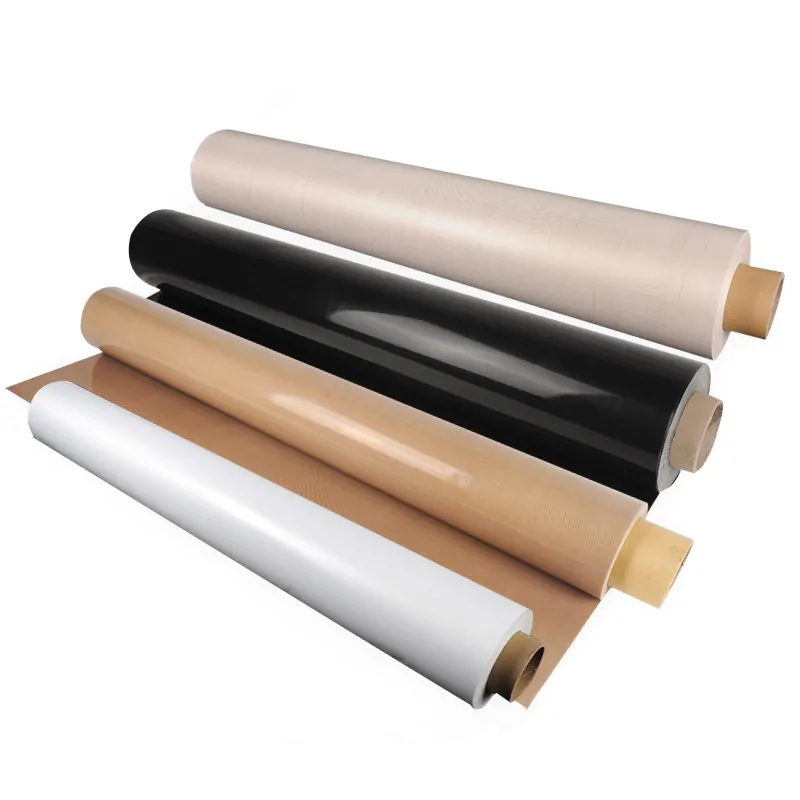

On conveyor belts, PTFE-coated glass fiber materials are one of the most extensively used options.

The benefits of PTFE-coated materials are the mix of PTFE safe (FDA criterion), heat resistance (ASTM-D6413 basic -325 ℃), and glass fibers have outstanding abrasion resistance and mechanical stamina, making them optimal for usage as food-grade conveyor belts.

Each of these applications calls for a particular thermal insulation service that not just fulfills particular thermal insulation demands yet likewise rigorous health requirements while fulfilling personal usage specifications. Silicone fiberglass coat coats for cooled piping should have a high dampness resistance to manage feaspossibledensation and constant flushing for regular cleansing. The ceramic fiber insulation coat inside the kiln is required to satisfy the heat stress over 1000 ° C and is safe and entirely safe.

While the value of insulation products in food handling is mainly concentrated on high food quality and success, there are many factors why insulation products supply excellent returns in the food handling market.