Email: sale10@kfqizhongji.com Hours: 24 Hour Service - 7 Days a Week

Location: No. 299, Jincheng East Road, Xinwu District, Wuxi City, Jiangsu, China

Email: sale10@kfqizhongji.com

Phone: +86-18118900837

Product Details

Weave Type | Twill Woven,plain Woven Or Customized | Surface Treatment | PTFE Coated |

Material | Fiberglass | Coating | Two Side PTFE Coated |

Thickness | 0.42mm | Width | 1000~4000mm |

Standing Temperature | -70 To +330 Degree C | Type | PTFE Coated Fiberglass Cloth |

Good Feature | Corrosion Resistance, Flame Retardant, Heat Insulation, Non-stick, Weatherproof | Application | Fire, Welding, Heat Retardant |

Color | Black,green,grey And Customed Colors | ||

Highlight | ptfe coated fiberglass cloth,ptfe coated glass fabric | ||

Product Description

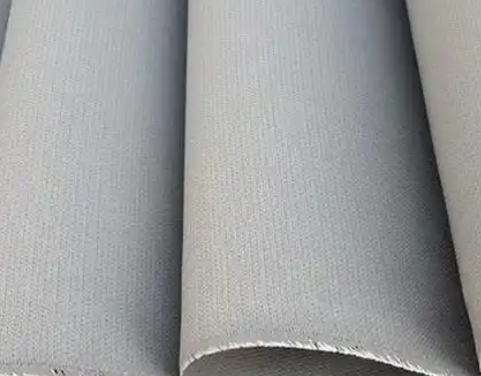

0.42mm High Temperature Resistance Ptfe Fiberglass Coated Fabric for the heat shield and fire/welding

PTFE glass fabrics are made of woven fiberglass that has been coated with PTFE. They are designed for a wide range of applications. They have a nonstick surface, withstand temperature to 620° f. They are chemically inert, have the tear-resistant ability and have excellent electrical properties. Their applications include thermal insulation, welding protection, fire protection, chemical plant, oil refinery, shipyard, conveyor belts, gaskets, seals, fabric air duct connectors, fabric air distribution ducts, and so on.

BASE FABRIC | Base fabric style No. GF430P | ||

| (metric) | (English) | Test methods |

Weave | 4H Satin | Crowfoot |

|

Yarn |

|

|

|

Warp | EC9 136 1﹡0 | ECG 37 1/0 |

|

Weft | EC9 136 1﹡0 | ECG 37 1/0 |

|

Construction |

|

|

|

Warp | 18 ± 1 ends/cm | 48 ± 3 ends/inch | ASTM D 3775-96 |

Weft | 12.6 ± 1 picks/cm | 32 ± 3 picks/inch | ASTM D 3775-96 |

Weight | 430 ± 30 g/m2 | 12.6 ± 0.9 oz/yd2 | ASTM D3776-96 |

Thickness | 0.37 ± 0.06 mm | 0.015 ± 0.002 inch | ASTM D1777-96 |

COATED FABRIC | Coating style No. PTFE245-8018 | ||

Coating | PTFE coated on both sides | ||

Weight | 610 ± 20 g/m2 | 18± 0.6 oz/yd2 | ASTM D3776-96 |

Thickness | 0.45± 0.02 mm | 0.017 ± 0.0007 inch | ASTM D1777-96 |

Color | Black |

| |

Fire resistance | Flame retardant |

| |

Antistatic | Yes(Static Dissipative) |

| |

Temp resistance | Glass fabric up to 550℃ (1000℉) PTFE coating up to 330℃ (620℉) | ||

Properties: temperature up to +330°c, non-stick surface, chemically inert, high tensile strength, excellent electrical properties, waterproof, resistance to weather, easy to clean.

Applications:

-- welding blanket and curtains

-- fire doors/curtains/blankets

-- thermal insulation

-- expansion joints

-- chemical plant, oil refinery, shipyard, forge

-- other fire and smoke control systems

PTFE coated fiberglass fabric features high temperature resistance, corrosion resistance and electrical insulation, making it suitable for harsh environmental conditions and providing long-term stable solutions.

Exploring the safety of PTFE coated fiberglass fabric, known for its Teflon coating and robust build, is essential. Is this coated fabric truly reliable?

Ceramic fiber wool can work continuously in an environment of 983°C (1800°F), up to 1260°C (2300°F), and the melting point temperature of ceramic fiber paper is 1648.9°C (3000°F).

Food handling strategies differ extensively, yet some typical instances that count on reliable warm monitoring consist of cooking, emulsifying, fermenting, sterilizing, and roasting.

Advantages and disadvantages of fire blankets: portable and quick to extinguish initial fires, heat insulation and protection, but limited by temperature resistance and coverage area.